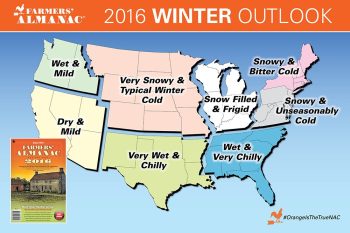

Fall is the perfect time to prepare your facility roof for the coming cold. In many regions of the U.S., […]

Winter’s coming, and you’re worried about your commercial roof’s readiness. You’re not alone. Cold weather can wreak havoc on your […]

Winter Isn’t Coming. It’s Already Here For many people in the U.S. winter is already here. Snow is currently falling […]

Get prepared for winter now – plan for your snow removal. A fresh, lofty snow can add 20 lbs. of […]

Heavy snows, cold temperatures, and other winter effects send most facility managers indoors to focus on maintaining a comfortable interior […]

There’s still time to reduce your seasonal utility costs before Old Man Winter sets in for good. Many parts of […]

Fall is the perfect time to prepare your facility roof for the coming cold. In many regions of the U.S., […]

Hailstorms top the list of potentially destructive weather events that can result in low-slope roof damage. Once compromised, heavy snow […]

Winter is Right Around the Corner Your roof is a critical and substantial part of your facility’s defense against the […]